Molecor highlights in its values the firm commitment to the protection of the environment through an effective management that promotes the prevention of environmental pollution, and work for an increasingly sustainable development. We have an Integrated Quality and Environmental System according to ISO 14001:2015, certified by AENOR.

In order to contribute to the decarbonization of our plants, a system of photovoltaic panels has already been implemented in our Loeches plant with a PPA (Power Purchase Agreement) system signed with POWEN, and we continue working in the rest of our production plants. Plans have also been carried out to reduce electricity consumption with actions such as the installation of dry-coolers in Antequera and Alovera, change of lighting to LED in Alovera, replacement of the injector with lower shutdown and reduction of consumption, finally resulting in reductions in consumption in kW.h/Tn of 4.04% in the overall Alcázar plant, 3.95% in the Orientation section in Antequera, or the reduction of 8.47% in the overall accessories in Alovera.

We have also worked to minimize the environmental impact with actions such as the investment in new machinery at the Alovera and Loeches plants, which reduce oil and absorbent consumption, as well as lower energy consumption.

The reduction in box consumption at Alovera was achieved by improving the transport ratio and by purchasing agricultural containers instead of cardboard boxes. The introduction of customers buying full pallets that facilitate loading and increase orders for larger boxes resulted in the elimination of the use of small boxes.

In Alovera, 72.6% less packaging containing hazardous substances was produced than in previous years, since thanks to the elimination of Pb and the use of Ca-organic based stabilizer, the waste generated has been managed as non-hazardous waste.

Solid urban waste has been reduced by 11.6 tons at the Alovera plant, thanks to the separate management of FILM - plastic bags (recyclable material).

Fluorinated gas refrigeration equipment has been eliminated at the Alcázar de San Juan plant and replaced with modern equipment with less environmental impact and lower energy consumption.

In general, all the production plants define specific actions to improve in this field, and the monthly monitoring of these actions is done through indicators such as industrial oil generation, generation of absorbents, reduction of electricity consumption and reduction of own balances, etc., all of them aimed at minimizing the environmental impact.

At Molecor we work to ensure that all our products have environmental advantages in all phases of their life cycle, from the extraction of raw materials to the final disposal of waste, including the manufacture and use of the products. So our products enable the construction of sustainable environments (SDG 11).

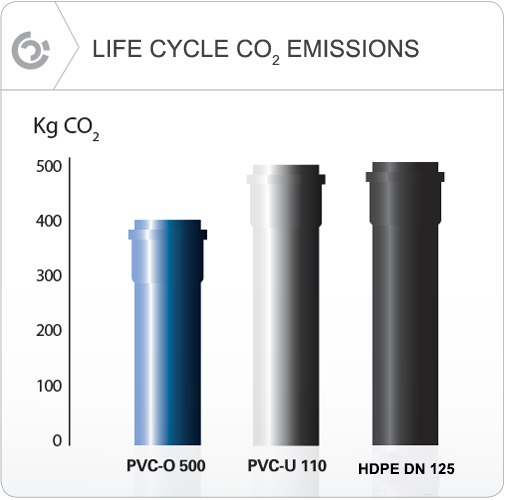

An example of this are the TOM® pipes and ecoFITTOM® fittings made of Oriented PVC, which have been presented as the most ecological solution of all those existing in the market, due to their better contribution to the correct sustainable development of the planet, as shown by different studies worldwide, among which we can highlight: "Estimation of energy consumption and CO2 emissions associated with the production, use and final disposal of PVC, PEHD, PP, Cast Iron and Concrete pipes" (Polytechnic University of Catalonia), and environmental label "PVC-O Environmental Product Declaration TEPPFA" (The European Plastics Pipes and Fittings Association).