The best fire protection on the market

The evolution of construction processes, permanent research into new materials and the need to construct more comfortable and safe buildings are requirements that it takes into account in order to provide new solutions to the market. Thanks to this level of demand, the AR® Soundproofing System complies with current regulations, meeting all the requirements of the Technical Building Code (CTE).

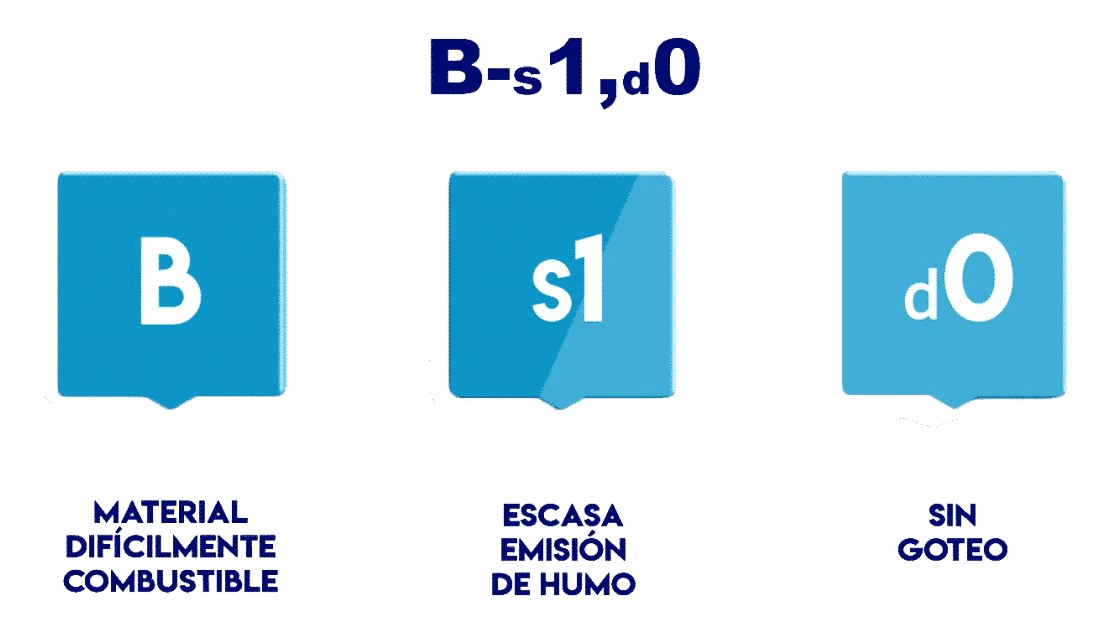

The AR® soundproof system has a reaction to fire classification B-s1, d0, the highest that a plastic material can obtain. This means that the system can be installed in all types of buildings, regardless of their use, complying with all the requirements of the Technical Building Code in the event of fire.

Not all plastics have the same fire behaviour: there are plastic materials that by their nature react by spreading flames during a fire and contributing to the spread of the fire.

The AR® Soundproof Evacuation System, manufactured in PVC-U and additivated with flame retardant compounds, acts as a flame retardant, reducing the spread of fire during a fire, complying with the requirements of the CTE.

The classification B-s1, d0 according to UNE-EN 13501 has the following meaning:

FIRE PERFORMANCE OF THE MATERIAL

- A1= Non-fuel. No maximum contribution to fire

- A2= Non-fuel. No minor contribution to fire

- B = Fuel. Very limited contribution to fire

- C= Fuel. Limited contribution to fire

- D= Fuel. Medium fire contribution

- E= Fuel. High contribution to fire

- F= Unclassified

SMOKE PRODUCTION RATE

- s1= 30 m²/s² [low and slow opacity]

- s2 = 180 m²/s² [medium opacity]

- s3 = non-performing or non-compliant S1 and S2 [high and fast opacity]

FLAMING DROPLETS/PARTICLES

- d0= No flaming particulate droplets within 600 sec.

- d1 = No flaming particulate droplets, with a persistence of 10 sec., are produced within 600 sec.

- d2 = Non-performing or non-compliant d0 y d1

NF Me French quality mark for AR® system

A further step in fire protection in buildings

The NF Me mark certifies, by an independent accredited laboratory, a minimum expansion capacity of 800% of the pipe or fitting wall under the effect of temperature. This property makes it possible to obstruct the ductwork in case of fire and thus restore the flame-retardant character of the wall or slab. The ducts are naturally a point of passage of fire through walls and floors.

Both elements must therefore restore their flame-shortening character. Pipes and fittings with this certification have the property of increasing their thickness under the effect of strong heat. In the event of fire, this feature allows the certified product to “swell” on the inside and thus restore the flame-cutting character of the wall or slab.

To obtain this mark, two simultaneous conditions must be satisfied:

- On the one hand, a minimum Euroclass of reaction to fire according to EN 13501 of B-s3, d0.

- On the other hand, and as mentioned above, to obtain an expansion rate greater than 800% of the initial wall thickness of the pipe or fitting.

PVC test tubes of 5×5 cm are placed in an oven.

These specimens are subjected to the heat effect in the furnace.

PVC test tubes must increase their initial thickness by at least 800% to obtain the NF Me mark.