The governments are planning more environmental policies which implies greener and environmentally friendly solutions in all areas and to maintain a proper sustainable development ot the available resources due to the global warning problem which is affecting the planet.

As a contribution to improve this problem, TOM® PVC-O pipes become the most sustainable option that exists in the market due to their lower energy consumption and lower CO2 production throughout its long useful lifecycle, from raw material extraction, pipe production and usage of the pipeline.

PVC-O lifecycle

During the lifecycle of the PVC-O pipes manufacture, we can distinguish several phases:

1.- Production phase

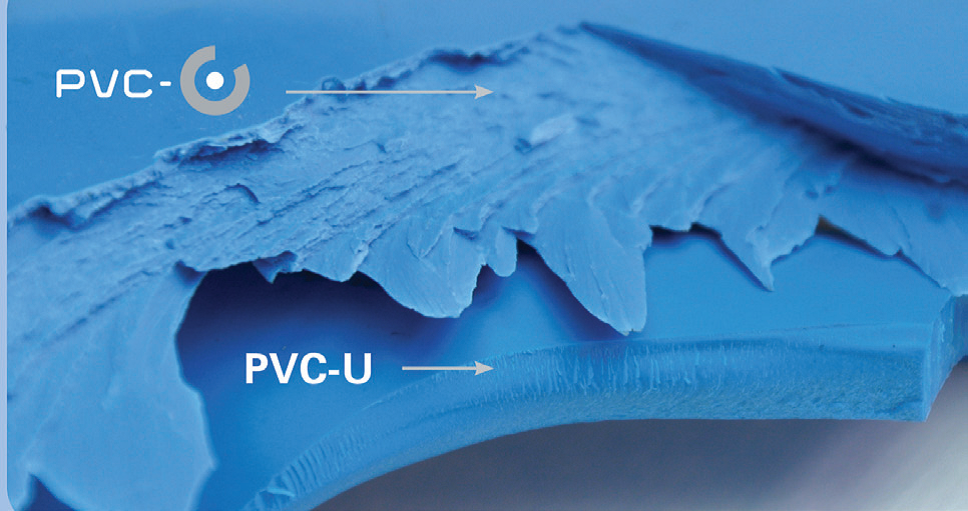

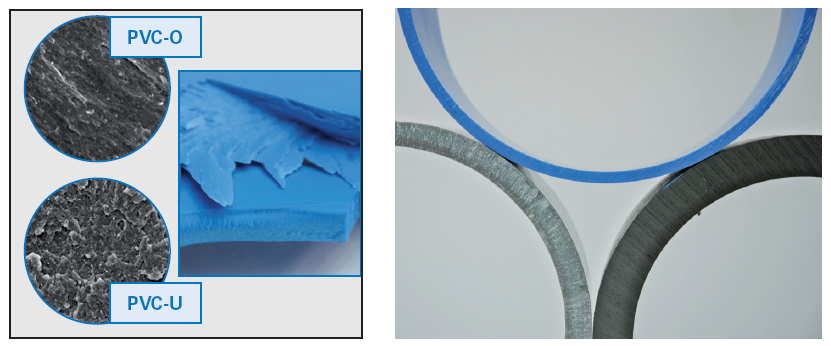

PVC-O pipes are manufactured by conventional extrusion and subsequent process of molecular orientation. The extruded base pipe, under certain conditions of pressure and temperature, is subjected to molecular stretching of the pipe, the rearrangement of the polymer molecules, forming a laminar structure on the pipe wall which significantly improves the mechanical properties of the pipe, while its chemical properties remain unchanged.

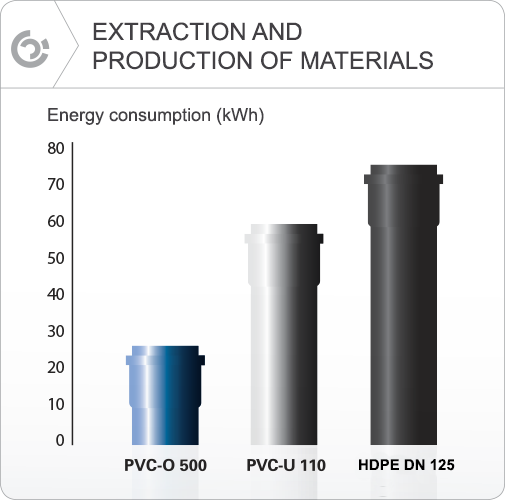

Although the pipe is produced using less raw materials, but due to its excellent mechanical properties, an optimization of pipe wall can be achieved. With less material consumptions during extraction and production also will resulting to energy saving.

Molecor's patented manufacturing process has a great energy efficiency in its production process and due to these features, the energy resources can also be optimized.

2.- Use phase

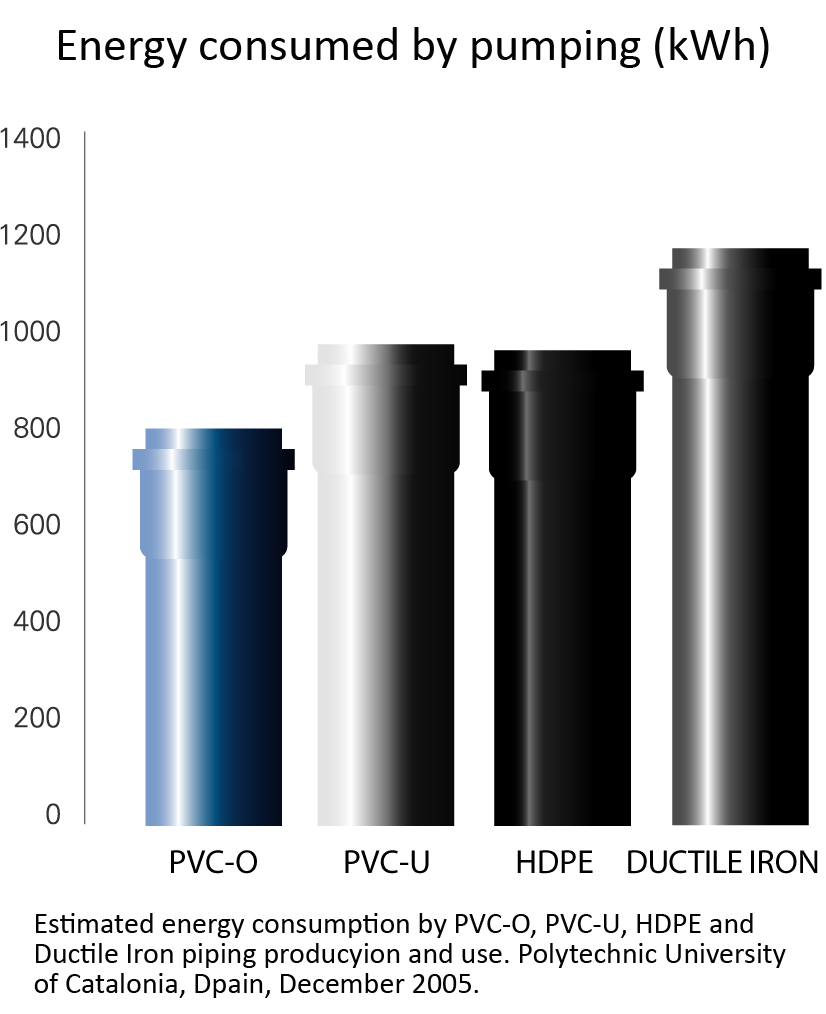

Good pipeline should be able to transport water in maximum capacity with lower pumping power, this can be achieved by using PVC-O pipes. As PVC-O pipes have a smooth surface, C value of 150, hence the water is able to be transported through pipeline with lower pumping energy usage.

Regarding the efficiency and energy savings that take place during this stage, we can distinguish several aspects:

• Transport optimization

Thanks to its light weight, less heavy machinery is used at project site. Less machinery will translate to less fuel usage and minimizing CO2 emissions.

• Installation cost and time efficiency

- Its lightness also helps in pipe handling which does not require special equipment to install.

- The efficient design of the socket allows the pipes being assembled with great ease.

Considering these two factors, fast and efficient installation can be greatly achieved. We are able to reduce the installation period at site while obtaining economic and social benefits by saving time and energy.

• Efficiency during operation

TOM® PVC-O pipes have a higher hydraulic capacity, hence it has larger bore which is able to transport between 15% to 40% more water in comparison to other materials and its diameter.

This increased hydraulic capacity is due to the greater useful section that these pipes present due to the optimization of wall thickness. Moreover, their smaller roughness causes the inner pipe surface is extremely smooth, thus the pressure losses are minimized and fluid can flow faster. All these benefits make that to transport the same amount of water less energy is needed, thus reducing energy consumption in pumping stage during use.

3.- Recycling or final disposal phase.

PVC is a 100% recyclable material which can be reused after its long useful life, mainly by mechanical recycling.

The PVC-O manufacturing process, due to its high technical requirement, which does not allow to use reprocessed or recycled material obtained from external sources and only permitted to use own repreocessed material in the production process.

Thus, consumption of raw materials and also the volume of waste generated is reduced.

Promoting a culture of reuse and recycling is reflected in the report of the European Commission in April 2004, and in the voluntary commitment of the actors in the sector of waste management at European level in the Vinyl2010 and VinylPlus programs.