Transport

First of all, it is important to note that the pipes must be transported in accordance with current traffic regulations. To optimize transport we recommend the following guidelines:

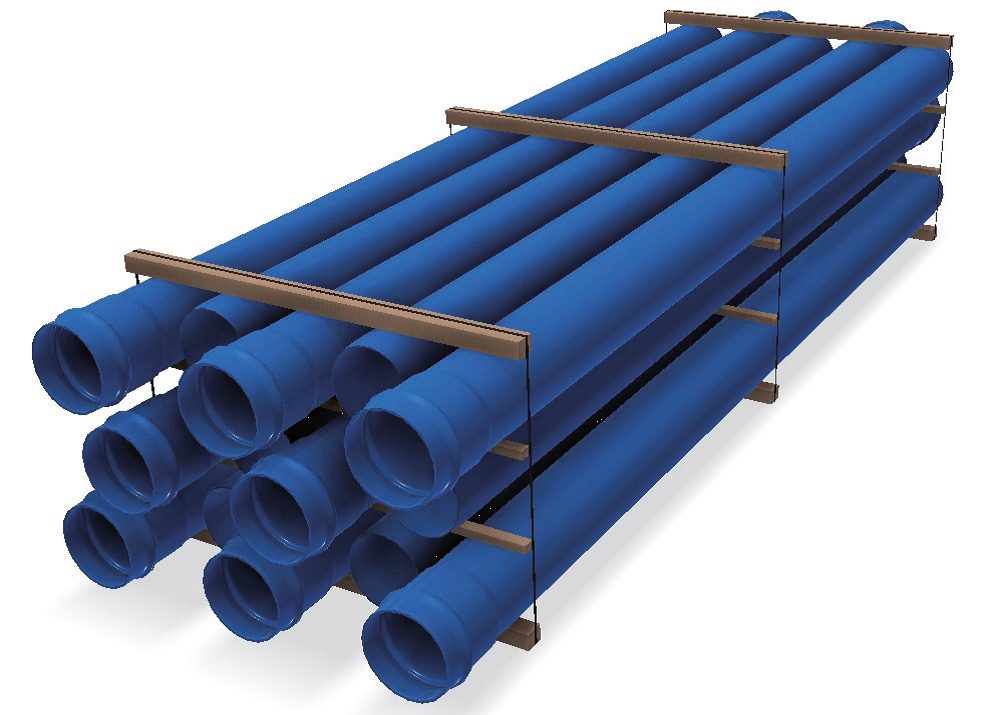

- If you are going to transport different diameters in one shipment, first place the larger diameters at the bottom. Use wooden pipe beddings with specifications that vary depending on the nominal diameter of the pipe.

- Leave the sockets free, alternating sockets and ends.

- During the reception of the pipes, check their condition.

Handling

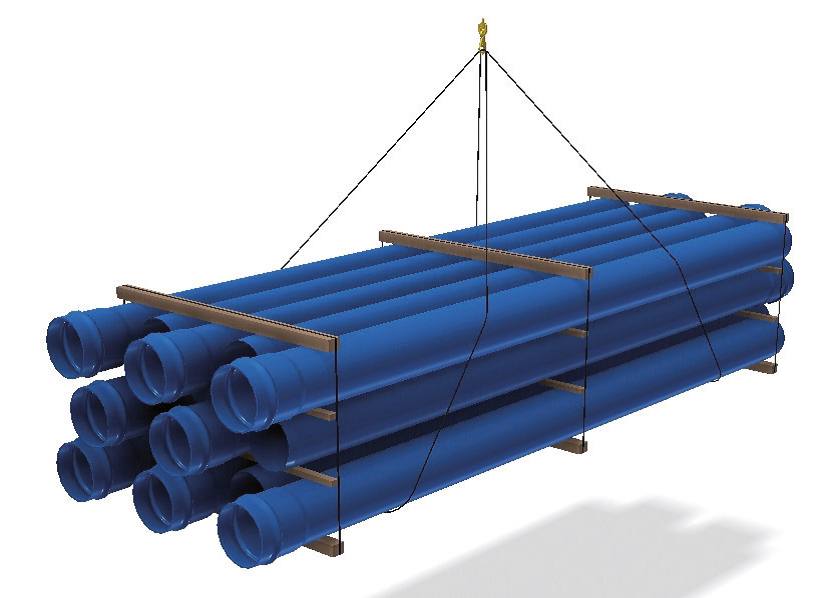

It is recommended to unload the pipes from the truck with the help of flat slings. Then, the loading and unloading pipes of DN ≥ 315 mm must be performed using mechanical equipment and for diameters of less than DN315 mm, using manual means.

Storage

For proper storage, the following is recommended:

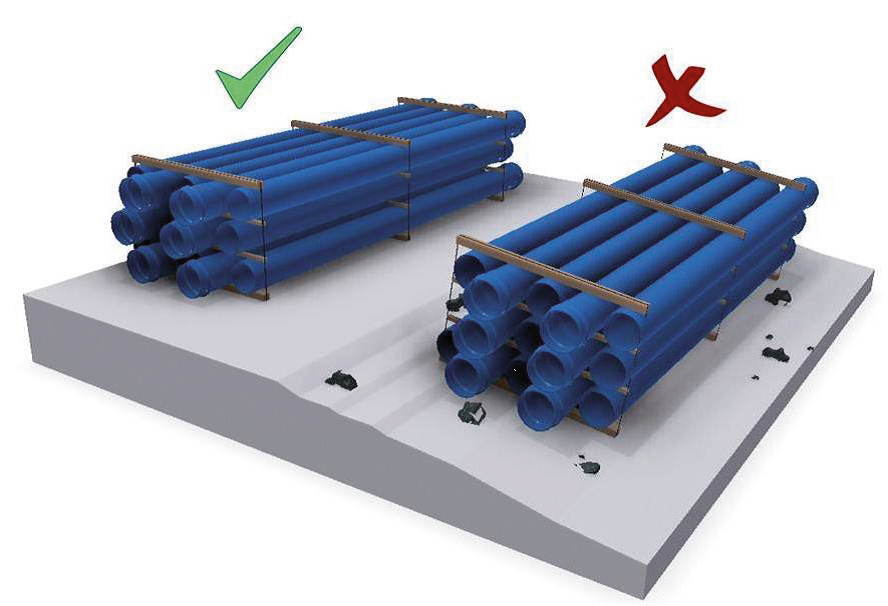

- Store the pipes horizontally on a flat area on supports placed every 1.5 metres to avoid the possible bending of the product.

- In particular, avoid especially the sockets being eroded on the ground, especially if they are made of stone, concrete or asphalt.

- Do not stack more than 1.5 metres high, as this could damage the pipes on the bottom or even cause the upper pipes to fall.

- The sockets must be free, alternating sockets and ends.

- In case of prolonged sun exposition, protect the pipes with an opaque material and with ventilation to prevent overheating. White colour is preferable because it avoids the over-heating of the pipes.

- Avoid covering the pipes with unventilated black tarps. Avoid placing the pipes close to heat sources acting permanently on the pipes. Prevent the pipes from constant contact with metal materials that can transmit an excess of temperature to pipes through their own conductivity.

Installation

Excavation

All the stones in the wall of the excavation must be removed as these could fall on the sand bed.

Hard objects such as stones, demolition waste, etc. must be removed from the bottom of the excavation.

After the geotechnical ground studies, the pipe support bed may be the ground or compacted granular material with a minimum thickness of 10 cm.

In aquifer land, the support bed materials should consist of particles of between 5 and 30 mm.

Assembly

In the case of Oriented TOM® PVC-O pipes, both the bevel and the mark on the smooth end are defined. This is important for a good location of the seal so as to locate the connection limit.

The main recommendations to ensure a good connection between the socket and the smooth end are as follows:

- Remove the protective caps.

- Check that the pipe is clean and in proper condition, paying attention to both the sockets and the ends.

- Check that the bevel is in perfect condition and free from cracks.

- Check that the gasket is well placed, clean and free of foreign objects (stones, sand, etc.).

- Lubricate the end bevel and the socket seal using coupling lubricant.

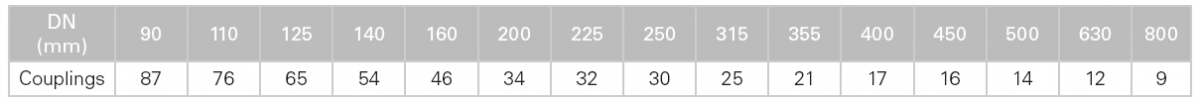

Number of couplings per kg of lubricant:

- Align the pipeline as correctly as possible horizontally and vertically.

- Insert only the edge of the bevel into the socket, so that the pipe is supported but the rest of the socket is free.

- In the case of pipes with nominal diameter ≤250 mm, insert with a firm push from the other end of the pipe to use the inertia produced by the movement, and thus insert the socket until the socket limit mark is hidden inside the socket.

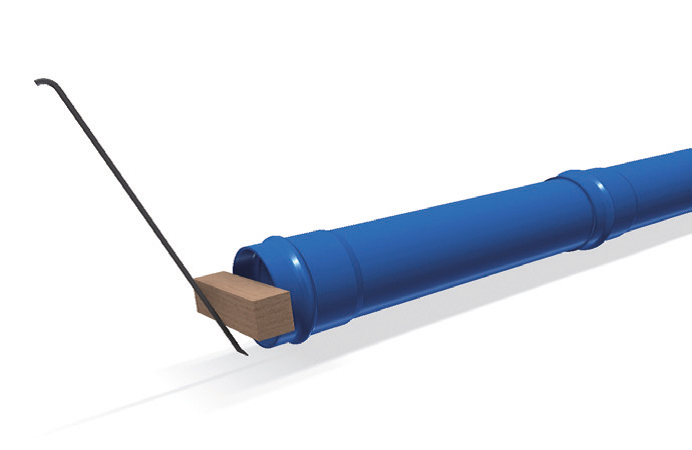

- In the case of large diameters >250 mm, mechanical means will be necessary to insert the pipe using materials such as wood, tractels or slings.

Testing on site and commissioning

In all matters relating to the installation, on-site tests and commissioning, follow the procedures of the UNE-EN 805 "Water supply" standard and/or the competent body. As you perform the assembly, test the pipe installed on completely installed sections. The test should be performed for lengths of 500 m and may vary depending on current regulations or guidelines issued by site management. The ends of the test section must be closed with the right parts; the pipe must be partially filled with the couplings uncovered.

The test pressure (STP) in N/mm2 (0.1 N/mm2 = 1 atm) will be:

a) If the water hammer has been calculated in detail:

STP = MDP + 0.1

b) If the water hammer has been estimated, the lower of the following values will be used:

STP = MDP + 0.5 and STP = 1.5 · MDP

MDP is the maximum design pressure, i.e. the maximum pressure that can be achieved in a pipe including the water hammer effect.

The commissioning of pipes for potable water supply must comply with the provisions of current legislation on cleaning and disinfection.